TRAY DRYERS

Introduction

A range of technologies is used for food drying which include tray and tunnel dryers, spray, roller and

freeze dryers. With the exception of tray dryers, none of these are appropriate, in terms of cost and

output, for use by small and medium enterprises.

While sun drying on trays or in solar dryers can be considered as tray drying the term is normally

applied to small industrial systems with some form of air heater and a fan to pass air over the product

being dried. While small tray dryers are available from Europe and the USA, where they are used in

pilot plants and Universities, their cost (in excess of £25,000) makes them unaffordable and

uneconomic for producers in developing countries.

In the early 1980’s ITDG (now Practical Action) recognised the need for small, controllable, powered

tray dryers capable of producing high quality products that could be constructed by engineers in

developing countries to a great extent from locally available materials. The required basic

development work was carried out and there are now tray dryers, based on the principles developed

by ITDG, in some eight countries. The greatest up-take of the technology has been in Latin America

where probably over 100 units are now operational. The key point to bear in mind when considering

the local construction of such a dryer is to understand the basic principles involved and adapt them

to local conditions such as the dimensions of local plywood sheet, common stock steel sizes, social

conditions and fuel availability.

The tray dryer family

Practical Action is able to supply information to allow the construction of four types of dryer. In some

cases full drawings and a How to Construct and Use manuals are available together with a case study

book. Much of this information is in English and Spanish.

Basic principles

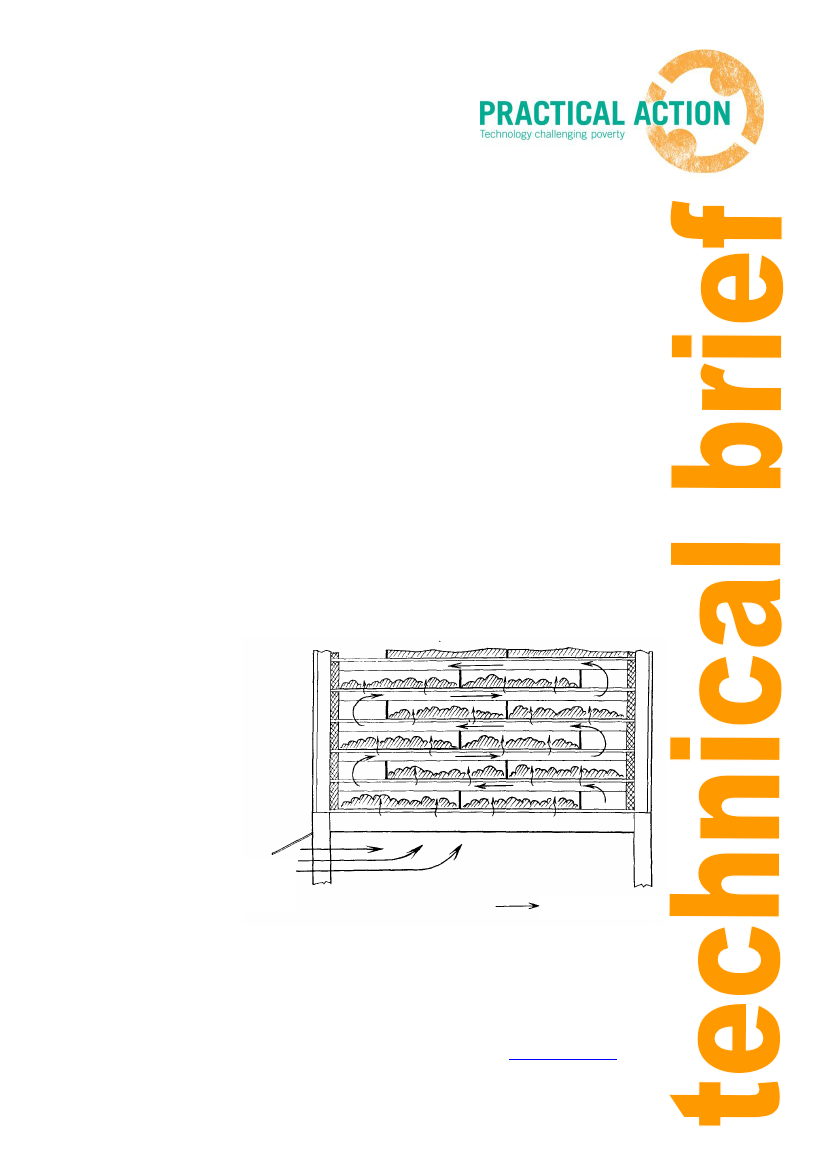

The dryers consist of a

cabinet containing trays

which is connected to a

source of air heated by

gas, diesel or biomass

such as rice husk. The air

temperature is usually

controlled by a thermostat

which is normally set

between 50 and 70OC. The

air enters the bottom of

the chamber below the

trays and then rises,

through the trays of food

being dried, and exits from

an opening in the top of

the chamber. In the

Warm

Dry Air

Direction of Air Flow

Figure 1: Basic parts and airflow pattern in a Practical Action dryer.

Practical Action, The Schumacher Centre, Bourton on Dunsmore, Rugby, Warwickshire, CV23 9QZ, UK

T +44 (0)1926 634400 | F +44 (0)1926 634401 | E infoserv@practicalaction.org.uk | W www.practicalaction.org

___________________________________________________________________________________________________________

Practical Action is a registered charity and company limited by guarantee.

Company Reg. No. 871954, England | Reg. Charity No.247257 | VAT No. 880 9924 76 |

Patron HRH The Prince of Wales, KG, KT, GCB